Technical Advantage

——创新的DYC催化剂技术平台

——Innovative DYC Catalyst Technology Platform

重油催化裂化反应中的主反应是大分子烃类在固体酸中心上所发生的正碳离子裂化反应过程。对于FCC催化剂而言,其结构与酸性具有同等的重要性。我们认为,当前的FCC催化剂设计应从上世纪80 年代提出的“配方设计理念”转变为“结构导向设计理念”,让催化剂的结构与酸性充分协同,以适应FCC 工艺及原料的变化要求。 催化剂结构包括:孔结构(开放式还是封闭式)及其分布(阶梯状还是同梯度)、活性中心(包括酸中心和其他功能中心)及其结构(均匀分布还是壳核分布)等;催化剂的酸性匹配包括:B酸与L酸的匹配、强酸与弱酸的匹配、酸量大小的匹配等。

The main reaction of RFCC is cracking reaction of high-molecular-weight hydrocarbons through carbenium ion intermediate on solid acid site. For FCC catalyst, pore architecture is as important as acidity. We believe that FCC catalyst design of today should transform from “Formula Design” to “Structure-Oriented Design”, achieving effective synergy between pore architecture and acidity to meet requirements from FCC processing and feedstock. The pore architecture of FCC catalysts includes pore distributions and pore structure (open type, close type), active sites species (acid sites and other functional centers) and its structure (uniform distribution, core-shell structure); The acidity matching of catalyst includes B acidity and L acidity matching, strong acidity and weak acidity matching, acid site number matching)

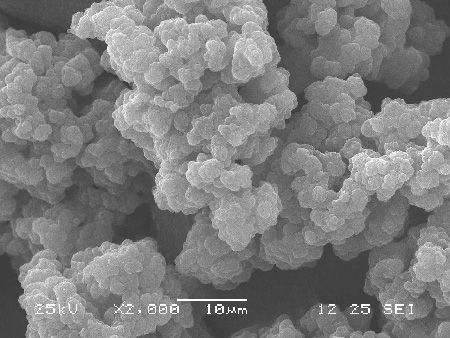

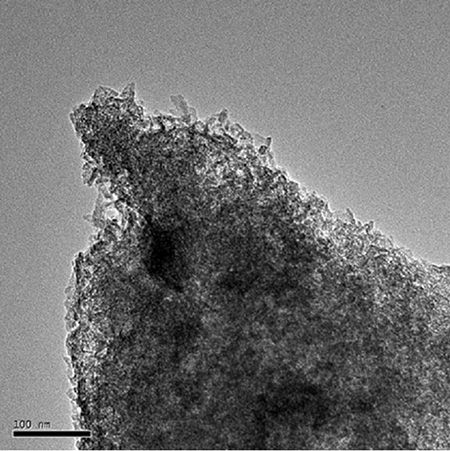

公司研发人员开发了具有丰富二次孔结构的低生焦Y分子筛催化材料制备技术和纤维状特种高活性氧化铝材料制备技术,这两种材料的制备工艺技术都已申请国家发明专利。下面是低生焦Y分子筛扫描射电镜(SEM)照片、纤维状特种高活性氧化铝透射电镜(TEM)照片和XRD图。

The Researcher of Duo You Technology developed rich mesoporous Y molecular sieve with low coke selectivity and fibrous high activity alumina preparative technique, and both technologies have applied for the national invention patents. The SEM photos of low coke Y molecular sieve, TEM photos and XRD patterns of the fibrous high activity alumina are shown below.

图 1 低生焦Y分子筛扫描电镜(SEM)照片

Figure 1 SEM Photo of Low Coke Y Molecular Sieve

图 2 纤维状特种高活性氧化铝透射电镜(TEM)照片

Figure 2 TEM Photo of Fibrous High Activity Alumina

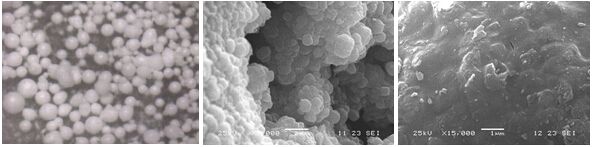

同时,公司技术人员从催化裂化反应机理出发,按照“结构导向”的思路,以低生焦Y分子筛催化材料和纤维状特种高活性氧化铝材料为基础,采用了高固含量催化剂制备技术,开发了创新的多友催化剂——“DYC系列FCC催化剂”技术平台。采用该技术平台制备的催化剂不仅提高了活性中心可接近性,并且从反应的角度解决了催化裂化过程中生焦率高的技术难题,同时还使该催化剂具有了优异的抗重金属污染能力。下面是DYC催化剂的扫描电镜(SEM)照片和孔径分布图。

At the same time, starting from catalytic cracking mechanism, following the "structure - oriented" idea and on the basis of low coke Y molecular sieve and fibrous high activity alumina, the company's technical staff adopted high solid content of catalyst technology to develop innovative Duo You catalyst – “DYC series FCC catalyst” technology platform. The catalyst prepared by technology platform not only improves accessibility of catalyst active sites, and solves the difficult problem of high coke yield during catalytic cracking process from the reaction mechanism, but also has excellent resistance to heavy metals. The SEM Morphology and pore size distributions of DYC catalyst are listed below.

从图3我们可以看出DYC技术平台制备的催化剂具有很好的球形度和开放性的孔结构(左图),与常规裂化剂的电镜照片比较可以明显看出两者的差异。在相同的放大倍数下,DYC技术平台制备的催化剂表面可以非常清楚地看到分布在微球上的分子筛颗粒和呈阶梯状分布的孔道结构,而传统工艺生产的催化剂表面形貌则呈板状结构。

From Figure 3 we can see that catalysts prepared on DYC Technology Platform showed very good sphericity and open pore architecture (left photo),compared to the SEM photo of common cracking catalyst, clear difference can be found.. With the same amplification factor, zeolite particles locating on microsphere and porous wall with multilevel pore-size distribution (middle photo) can be clearly seen on surface of catalyst prepared by DYC Technology Platform. However, the surface of catalyst prepared by traditional technology is platy due to binding agent. Neither zeolite nor pore structure is obvious.

DYC颗粒电镜照片(50倍) DYC单个颗粒电镜照片(8000倍) 常规裂化剂单个颗粒电镜照片(15000倍) SEM photo of DYC particles(50X) SEM photo of DYC single particle(8000X) particle (15000X)

图3 DYC技术平台催化剂与常规裂化剂形貌对比

Figure 3 SEM Photos of DYC Catalyst and Common Cracking Catalyst

由于DYC技术平台制备的催化剂,分子筛直接分布在其孔道表面(中图),使得重油大分子可以直接扩散接触到分子筛的酸中心,提高了催化剂活性中心可接近性,有利于重油大分子的裂化反应和产物的扩散分离,可显著提高催化剂的活性和选择性。

As zeolites in catalyst prepared by DYC Technology Platform cover directly on surface of porous wall (middle photo), macromolecule of heavy oil can diffuse readily to acid sites of zeolites, so that the accessibility of active sites is enhanced. Meanwhile, diffusive separation of cracking product has been improved, activity and selectivity of catalyst are also significantly increased.

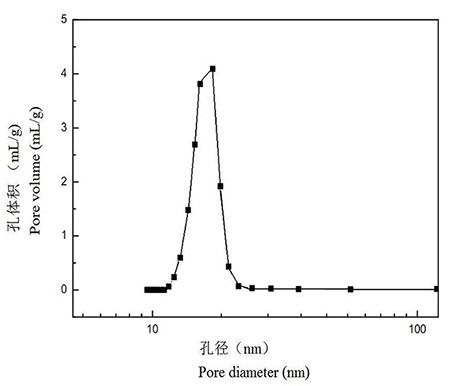

图 4a 纤维状活性氧化铝的孔径分布图

Figure 4 pore size distributions of fibrous activity alumina

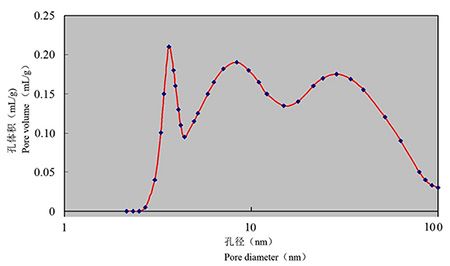

图 4b低生焦催化剂孔径分布图

Figure 4b pore size distributions of DYC catalyst

从图 4孔径分布图可以看出纤维状活性氧化铝的孔径主要集中在10-20 nm,是一种大孔径的氧化铝材料。催化剂中引入该种氧化铝后,不仅可以显著提高催化剂 10~60 nm中孔比例,而且还可以形成相当数量的60~100nm的大孔和超大孔,并且为开放性的孔结构和阶梯状的孔分布。因此,可以认为DYC催化剂在结构设计上解决了活性中心的可接近性问题。

In Figure 4, we can see that the pores of fibrous activity alumina are mainly concentrated in the range of 10-20 nm, and the fibrous activity alumina is a large aperture alumina material. When the alumina was added into the catalyst, both of the proportion of 10 ~ 60 nm mesopore and the proportion of large pore and super pore of catalyst were improved significantly, and the structure of pore was open distribution. So we can say that DYC catalysts resolved the problem of accessibility of catalyst active sites in structural design.

因此,该技术平台制备的催化剂具有以下特点:

Therefore, FCC catalysts produced on DYC technology platform have such characteristics:

(1) 开放性、梯度状分布的孔道结构:

不仅缩短了原料油和裂化产物分子扩散进出催化剂的路径,减少了热裂解的比例,限制了产物的深度裂解,增加了对产品和焦炭的选择性;而且有利于汽提段水蒸汽对于待生剂中吸附分子的汽提作用,降低了可汽提焦。

(1) Open and Graded distribution of pore structure

The open pores shorten the raw oil and product molecular diffusion path in catalyst, reduce the ratio of thermal pyrolysis of raw oil, limit the deep cracking of product, improve the selectivity of products and coke was improved, make contribution to the stripper steam treatment agent of molecular adsorption stripping effect, and reduce the catalyst-to-oil coke.

(2) 特殊分布的结晶分子筛

DYC催化剂中不仅分子筛含量高,而且分子筛在催化剂微球表面和孔道中暴露的比例也高于常规FCC催化剂。利用分子筛表面酸中心的高催化活性和选择性,能够促进重油大分子包括原料中部分可转化的残炭和生焦前身物物种发生催化裂化反应,降低非选择性反应比例,从而有利于在增强重油转化能力的同时减少催化焦和附加炭的生成。

(2) Crystal molecular sieve with special distribution

The content of molecular sieve in DYC catalyst is high, and the exposure proportion of molecular sieve on surface and in pore passage of catalyst microspheres is higher than that of conventional FCC catalyst. The high catalytic activity and electivity of surface acid site of molecular sieve are suitable for promoting catalytic cracking of heavy oil macromolecule including some convertible carbon residues and green coke precursors in raw materials, to reduce the proportion of nonselective reactions, thus conducive both to improving heavy oil conversion ability and to decreasing production of catalytic coke and additional carbon.

(3)抗碱性氮和重金属污染能力强

DYC催化剂的配方中相对提高了Y型分子筛的含量,这就增加了该催化剂酸性中心的数量,使其抗碱性氮的能力大大增强;同时,DYC催化剂的配方中还加入了纤维状高活性氧化铝,该氧化铝具有较强的重金属捕集容纳能力,可降低重金属所引发的非选择性反应,使催化剂抗重金属污染的能力大大增强。

(3) Strong basic nitrogen and heavy metal pollution resistance

The content of Y molecular sieve is increased relatively in the formula of DYC catalyst, which raises the quantity of acid sites of the catalyst, greatly strengthening its resistance to basic nitrogen; meanwhile, fibrous high-activity aluminium oxide is also included in the formula of DYC catalyst, and the aluminium oxide is of comparatively strong heavy metal trapping and containing capacity, which reduces nonselective reactions caused by heavy metal, and significantly enhances catalyst’s resistance to heavy metal pollution.

(4)轻质油收率高

DYC催化剂具有一定数量的大孔和超大孔,能够使重油大分子更加容易地进入到催化剂孔道中进行催化反应,从而使油浆收率降低,轻质油收率提高。同时,纤维状高活性氧化铝基质材料与不同品种的改性分子筛进行匹配,可以调变催化裂化反应过程中不同类型反应的比例,以适应不同类型原料油的裂化反应,尤其是能有效提高催化裂化反应的比例,降低热裂解反应的比例,从而能较大幅度地降低生焦,增加轻质油收率;特别是高含量的Y分子筛能促使部分柴油分子转化为汽油分子,使汽油收率提高。

(4) High light oil yield

DYC catalyst has large pore and ultra-large pore at certain quantity, to facilitate the entry of heavy oil macromolecule to the pore passage of catalyst for catalytic reaction, thus reducing the yield of slurry oil and promoting that of light oil. Meanwhile, the matrix material of fibrous high-activity aluminium oxide is matched with various modified molecular sieves, which modulates the proportion of different reactions during catalytic cracking to adapt to cracking of different kinds of raw oils, thus decreasing green coke greatly and increasing the yield of light oil; particularly, the high-content Y molecular sieve prompts conversion of diesel oil molecules to gasoline molecules to promote the yield of gasoline.

山东多友科技有限公司可针对各个炼厂的装置特点、原料油性质、产品分布情况和目标产品的意愿,量体裁衣、调整配方,设计生产满足用户使用要求的专用催化剂。

Catalyst of Duo You Technology is tailor-made to satisfy operating requirements of users based on device features of each refiner, feedstock properties, product distribution and target products.